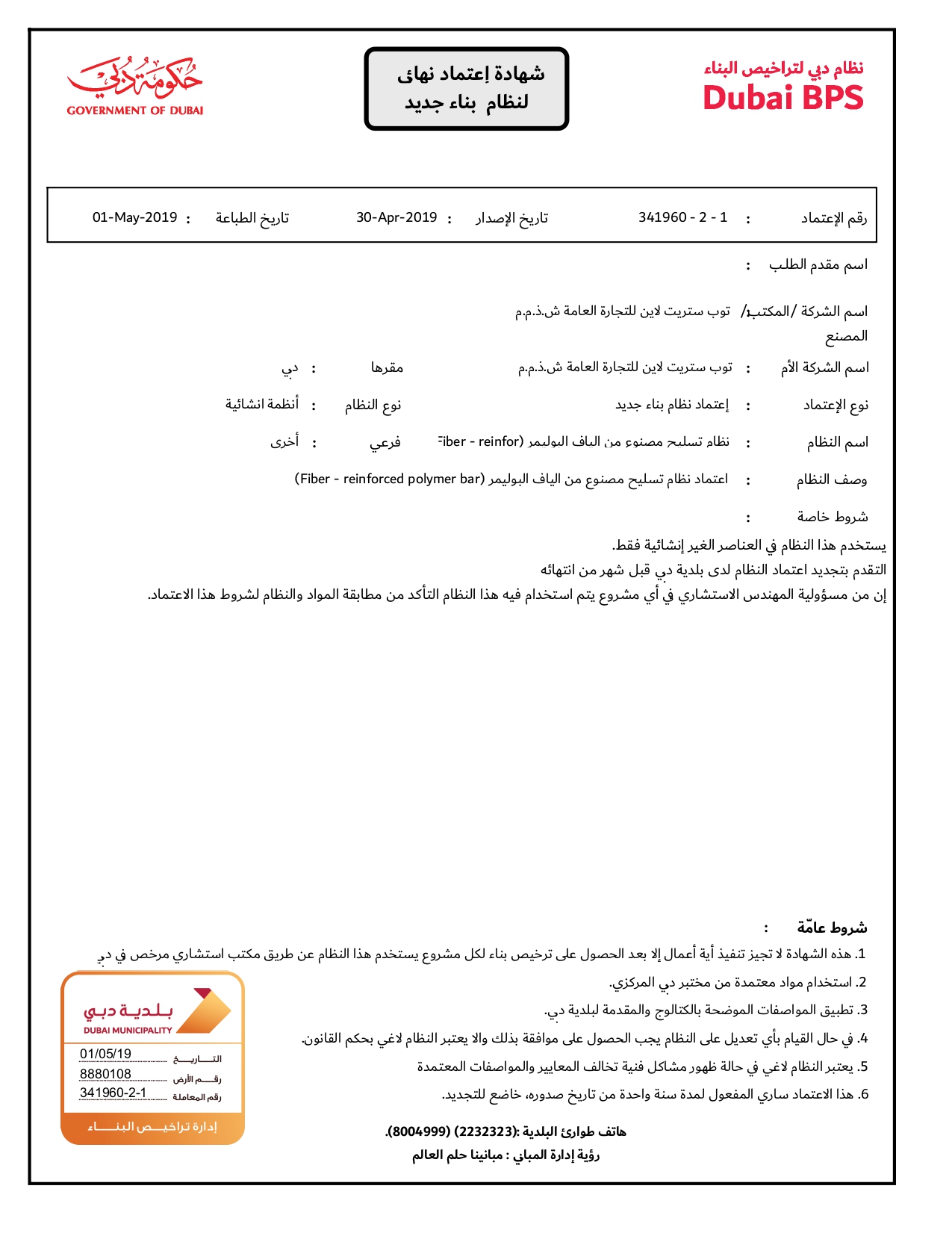

GFRP Rebar: Redefining Construction Standards

100% Corrosion Resistant

Lasts Over 100 Years

Trusted in Mega Projects

Withstands in Up to 100°C Heat

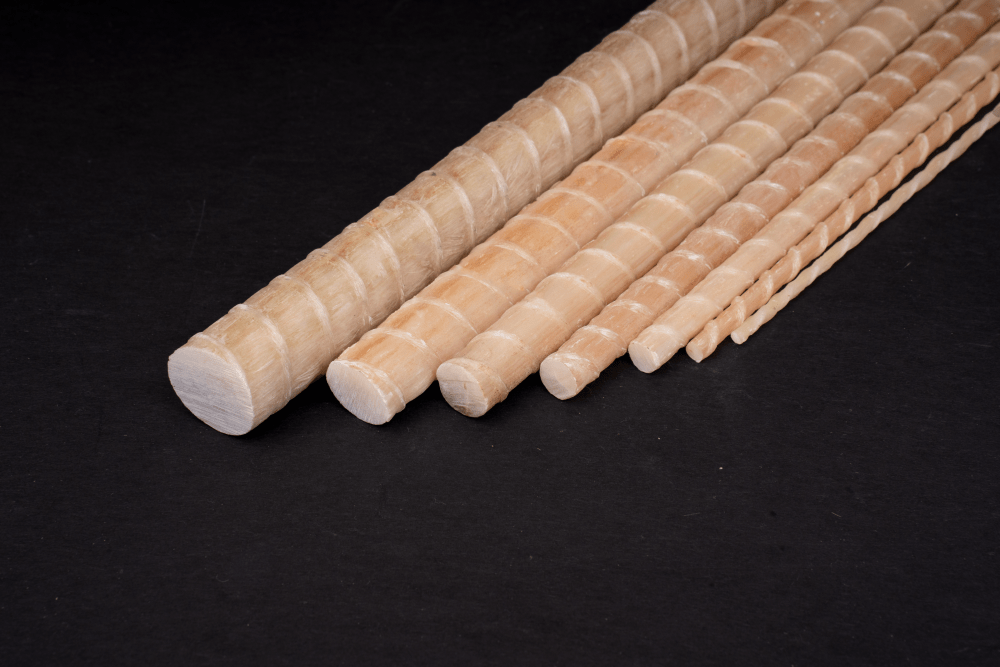

Glass Fiber Reinforced Polymer - GFRP Rebar

GFRP (Glass Fiber Reinforced Polymers) Rebars are the best composite rebar for construction material and building material. The use of GFRP composites rebars increased very well in the construction business. Our Rebars are two times stronger and 1/4 lighter than steel. Our rebars include high-quality corrosion-resistant epoxy resin that increases the lifespan of a concrete structure. GFRP Rebar is made of Glass Fiber and Polymer Rebar. Fiber Glass protects polymer resin.

MRG Composite Rebar has the best GFRP (Glass Fiber Reinforced Polymers) rebar price in India. We are the leading GFRP rebar manufacturer in India.

MRG GFRP Rebar Advantages

Corrosion Resistant

Stronger

Lighter

Cost Effective

Zero Maintenance

Longer Life Span

Corrosion Resistant

Stronger

Lighter

Cost Effective

Zero Maintenance

Longer Life Span

Eco Friendly

Dielectric

Easy To Transport

Water Resistant

Less Thermal Expansion

Radio Transparent

Eco Friendly

Dielectric

Easy To Transport

Water Resistant

Less Thermal Expansion

Radio Transparent

Durable

Lower Installation Cost

Easy Site Handling & Easy Cutting

Faster And Safer Installation

Reduced Concrete Coverage

Savings In Overlapping Cost

Durable

Lower Installation Cost

Easy Site Handling & Easy Cutting

Faster And Safer Installation

Reduced Concrete Coverage

Savings In Overlapping Cost

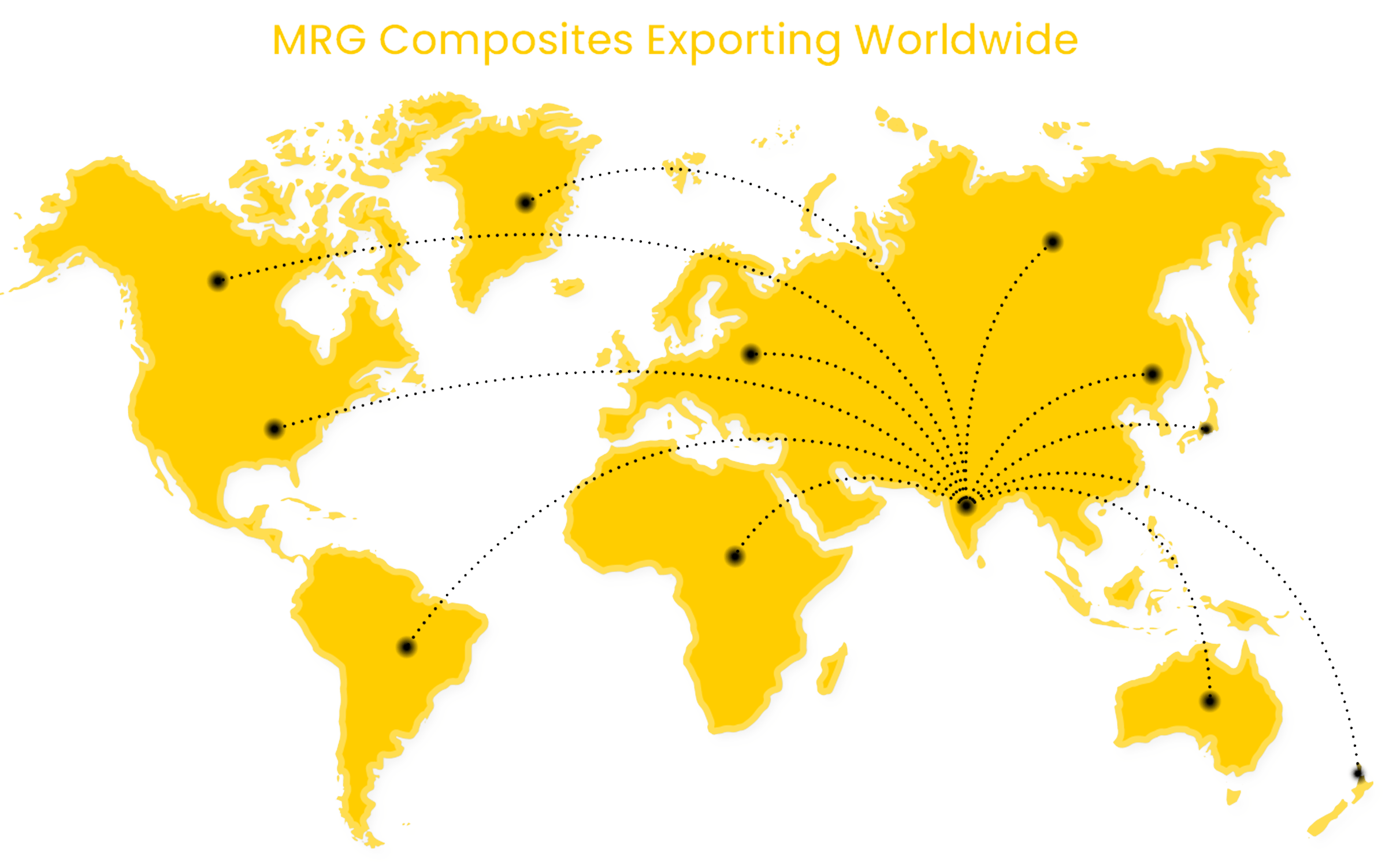

Export Expertise

Successfully exported to South Korea, Dubai, Budapest and more.

Timely Production

Standard 15–20 days lead time.

Flexible Shipping

Options for 20FT / 40FT containers and LCL shipments

Transparent Documentation

Complete export paperwork for smooth customs clearance.

Flexible Payment Terms

Multiple options tailored to international buyer needs.

All Pricing Terms Supported

EX-Factory, FOB, CIF, DDP, and more

Export Expertise

Successfully exported to South Korea, Dubai, Budapest and more.

Timely Production

Standard 15–20 days lead time.

Flexible Shipping

Options for 20FT / 40FT containers and LCL shipments

Transparent Documentation

Complete export paperwork for smooth customs clearance.

Flexible Payment Terms

Multiple options tailored to international buyer needs.

All Pricing Terms Supported

EX-Factory, FOB, CIF, DDP, and more

MRG Composites Export Process

Customer Inquiry

Product Consultation

Quotation & Finalization

Payment Confirmation

Production & Lead Time

Quality Inspection

Shipping & Documentation

Delivery & Support

TABLE OF SUBSTITUTION BY TENSILE STRENGTH

| MRG GFRP Rebars | Metal Rebars | ||

| 3 mm | 0.185 Kg | – | – |

| 3.5 mm | 0.280 Kg | – | – |

| 4.5 mm | 0.468 kg | 06 mm | 2.75 kg |

| 06 mm | 0.570 kg | 08 mm | 4.74 kg |

| 07 mm | 0.90 kg | 10 mm | 7.40 kg |

| 08 mm | 1.20 kg | 12 mm | 10.65 kg |

| 10 mm | 1.60 kg | 14 mm | 14.52 kg |

| 12 mm | 2.40 kg | 16 mm | 18.93 kg |

| 14 mm | 3.24 kg | 18 mm | 24.00 kg |

| 16 mm | 4.87 kg | 22 mm | 35.76 kg |

| 18 mm | 6.28 kg | 25 mm | 46.22 kg |

| 20 mm | 8.08 kg | 28 mm | 58.02 kg |

| 22 mm | 9.80 kg | 32 mm | 75.79 kg |

| 25 mm | 11.67 kg | 40 mm | 118.52 kg |

MRG Composites

The Pioneers Of GFRP Rebars In India.

4.5 out of 5 customers give us 5 stars?

Commitment to High-Quality Standards

MECHANICAL PROPERTIES OF MRG GFRP REBARS WHEN COMPARED TO METAL REBARS

| Material | Metal Rebars | MRG GFRP Rebars |

| Tensile strength(MPa Or N/mm^2 | 500 – 600 | 1000+ |

| Shear strength | 120 | ≥150 |

| Bond strength(MPa or N/ mm^2) | 14* | ≥11 |

| Compression(MPa or N/ mm^2) | 500 | 450 |

| Modulus of elasticity(Gpa) | 160 – 200 | ≥50 |

| Elongation (%) | 25 | ≥1.5 |

| Durability | Terms are prescribed in special building codes | 80 years+ |

| Density(Ton/m3) | 7.8 | 1.9 |

| Corrosion resistance to aggressive environment | Appearance of rust | Stainless material preserving properties even in alkaline concrete environment |

| Ecological compatibility | Ecologically friendly material | Does not emit harmful and toxic substances during storage and use |

| Electrical conductivity | Electrically conductive material | dielectric |

STANDARDS & DESIGN GUIDES OF GFRP REBARS IN INDIA & ACROSS THE GLOBE

IS 18255: 2023

Fibre-Reinforced Polymer (FRP) Rebars for Concrete Reinforcement – Methods of Test.

IS 18256: 2023

Solid round Glass Fibre Reinforced Polymer (GFRP) Rebars for Concrete Reinforcement – Specification.

IRC: 137-2022

Guidelines on use of fibre-reinforced polymer bars in road projects.

ACI 440. 1R-06 (2006)

“Guide for the design and construction of structural concrete reinforced with FRP Rebars”, American Concrete Institute

ACI 440. 3R-04 (2004)

“Guide for test methods for Fiber Reinforced Polymers (FRP) for Reinforcing or Strengthening Concrete Structures.

ACI 440R-07 (2007)

“Report on Fiber-Reinforced Polymer (FRP) Reinforcement for Concrete Structures,” ACI Committee 440.

ACI 440.1-15 (2015)

“Guide for the Design and Construction of Structural Concrete Reinforced with Fiber- Reinforced Polymer Bars,” ACI Committee 440.

ACI 440.3R-12 (2012)

“Guide Test Methods for Fiber-Reinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures,” ACI Committee 440.

ACI 440.6M-08 (2017)

“Specification for Carbon and Glass Fiber-Reinforced Polymer Bar Materials for Concrete Reinforcement”, ACI Committee 440

ACI 440.5-18 (2018)

“Specification for Construction with Fiber-Reinforced Polymer Reinforcing Bars,” ACI Committee 440.

AASHTO GFRP-1 (2009)

AASHTO LFRD Bridge Design Guide Specifications for GFRP – Reinforced concrete Bridge Decks and Traffic Railings”, American Association of State Highway and Transportation Officials.

FHWA-HRT-05-081 (2005)

“Design of Continuously Reinforced Concrete Pavements using Glass Fiber Reinforced Polymer Rebars.” Federal Highway Administration, US Department of Transportation.

FDOT (2021),

“Florida Department of Transportation Standard Specifications for Road and Bridge Construction.” Florida Department of Transportation.

AASHTO (2018),

“LRFD Bridge Design Guide Specifications for GFRP Reinforced Concrete,” American Association of State Highway and Transportation Officials.

CAN/CSA-S807-10

“Specifications for Fiber Reinforced Polymers”

CAN/CSA-S806-12 “

Design and Construction of Building Components with Fiber-Reinforced Polymers”

CAN/CSA-S6-06 (2006)

Fiber-Reinforced Structures, “Canadian Highway Bridge Design Code”, pp.693-728.

CSA CAN/CSA-S6-06 (2006)

“Canadian Highway Bridge Design Code.” Standards Council of Canada.

JSCE Series 23

“Recommendation for Design and construction of Concrete structures using continuous Fiber Reinforced Material”.

JBDPA Design Manual (2009)

“Japanese Design and Construction Guidelines for Seismic Retrofit of Building Structure with FRP composites.”

DIN1045-1

“EN-Concrete Reinforced and Pre-stressed Concrete Structures – part 1: Design and Construction.”

Fib Bulletin No.40 (2007) “FRP Reinforcement in RC Structures” 7.

Transport for NSW (2020)

“Technical Guide Design of Continuously Reinforced Concrete Pavement using Glass Fibre Reinforced Polymer (GFRP) Bars at Traffic Loop Locations,” Document Number P-G-008, New South Wales Government, Australia.

EN-13706 (EUROPE)

CNR-DT 203 & CNR-DT 205 (ITALY)

GOST 9.071-76 (RUSSIA)

ASTM D570-98 (2018)

“Standard Test Method for Water Absorption of Plastics,” ASTM International.

ASTM D578/D578M-18 (2018)

“Standard Specification for Glass Fiber Strands,” ASTM International.

ASTM D792-20 (2020)

“Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement,” ASTM International.

ASTM D2584-18 (2018)

“Standard Test Method for Ignition Loss of Cured Reinforced Resins,” ASTM International.

ASTM D3171-15 (2015)

“Standard Test Methods for Constituent Content of Composite Materials,” ASTM International.

ASTM D7205/D7205M-21 (2021)

“Standard Test Methods for Tensile Properties of Fiber-Reinforced Polymer Matrix Composite Bars,” ASTM International.

ASTM D7617/D7617M-11 (2017)

“Standard Test Method for Transverse Shear Strength of Fiber-reinforced Polymer Matrix Composite Bars,” ASTM International.

ASTM D7705/D7705M-12 (2019)

“Standard Test Method for Alkali Resistance of Fiber Reinforced Polymer (FRP) Matrix Composite Bars used in Concrete Construction,” ASTM International.

ASTM D7913/D7913M-14 (2020) “Standard Test Method for Bond Strength of Fiber-Reinforced Polymer Matrix Composite Bars to Concrete by Pullout Testing” ASTM International.

ASTM D7957/D7957M-17 (2017)

“Standard Specification for Solid Round Glass Fiber Reinforced Polymer Bars for Concrete Reinforcement” ASTM International.

ASTM E1356-08 (2014)

“Standard Test Method for Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry.” ASTM International.

ASTM E2160-04 (2018)

“Standard Test Method for Heat of Reaction of Thermally Reactive Materials by Differential Scanning Calorimetry.” ASTM International. 20 21

Contact Us

Get high performance GFRP composite rebar at the best price on your next project

Address

Office No 601, Twin Star South Block, Near Nanamava Circle, 150 Feet Ring Road Rajkot- 360004